Dec 18th 2024

OCCAR Contract Extension

A new contract extension as part of the OCCAR Night Vision Capability Programme

Dec 18th 2024

A new contract extension as part of the OCCAR Night Vision Capability Programme

Nov 25th 2024

Exosens is pleased to announce its upcoming inclusion in the MSCI France Small Cap index

Nov 22nd 2024

Micro UAVs frequently integrate visible-spectrum and LWIR thermal cameras...

Nov 19th 2024

Image intensifiers solutions for single photon counting applications

Nov 18th 2024

Image intensifiers solutions for high-speed imaging, scientific and solarblind UV applications

San Francisco.

FROM Jan 25th 2025 TO Jan 30th 2025

Visit Exosens at BiOS Booth 8359 and Photonics West Booth 1827, in San Francisco

Nov 06th 2024

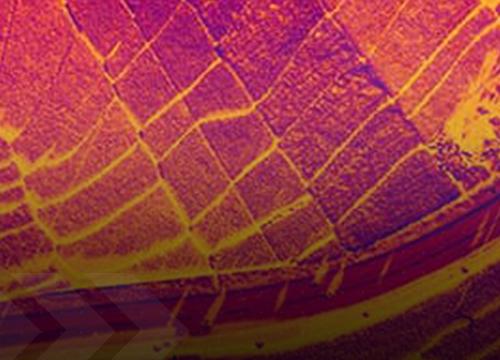

Infrared imaging and camera systems lead to innovative and powerful solutions.

Oct 28th 2024

Exosens today announces its revenue and adjusted gross margin for the nine-month period ended 30 September 2024.

Oct 22nd 2024

Exosens announces agreement to acquire NVLS (Night Vision Laser Spain), specialist in night vision equipment

Stay connected

Stay informed and connected to the latest news from Exosens by signing up.