In industrial and scientific fields, the need for precise, reliable insights into materials is paramount, whether for detecting structural weaknesses or for analyzing the composition of unknown compounds. By combining advanced nondestructive testing techniques and sophisticated material analysis, we can uncover hidden defects and perform accurate molecular identification, ensuring both structural integrity and chemical understanding. Exosens supports these efforts with state-of-the-art technologies in infrared imaging and mass spectrometry, providing tailored solutions for diverse applications across multiple industries.

The presence of cracks and defects changes the thermal properties of materials. Infrared imaging provides unique insights for remote inspection of various objects such as electronic components and artworks where non-contact analysis is more suitable. The correct interpretation of thermal flows can reveal the presence of structural changes within the material and prevent failures.

While infrared imaging reveals structural changes invisible to the naked eye, advanced detection technologies also play a crucial role in the analysis of inert compounds. To meet this complex challenge, Exosens provides highly sensitive and accurate detection solutions tailored for mass spectrometry applications.

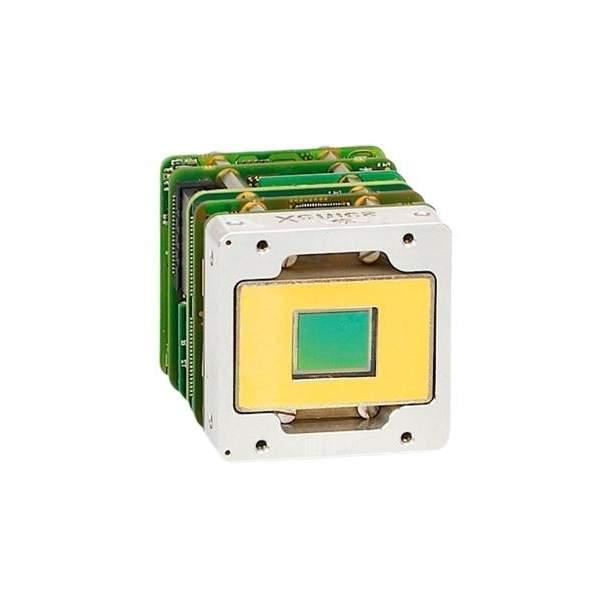

The need of being able to detect, identify and analyze unknown inert compounds remains a challenge for analytical companies and laboratories. In order to succeed and to identify specific molecules based on their weight, research labs, hospitals, universities and pharmaceutical companies have been using the latest and up-to-date mass spectrometry techniques. Exosens offers highly sensitive and accurate detectors that can be set up in different types of mass spectrometers : Liquid Chromatography Mass Spectrometry (LCMS), Gas Chromatography Mass Spectrometry (GCMS) and Residual Gas Analysis (RGA).

Exosens ion and electron detectors are custom design engineered for most of the world’s mass spectrometers. According to customer needs, Exosens provides detectors with superior sensitivity, a wider range of spatial or temporal resolution, and the ability to detect both positive and negative ions. Exosens has a strong track record in mass spectrometry, offering proven technology with high level of reliability.

Need some answers? Ask our experts!

Contact usNondestructive Testing

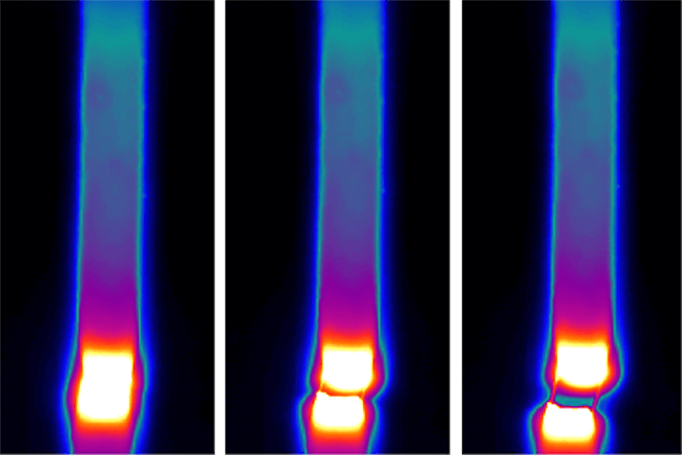

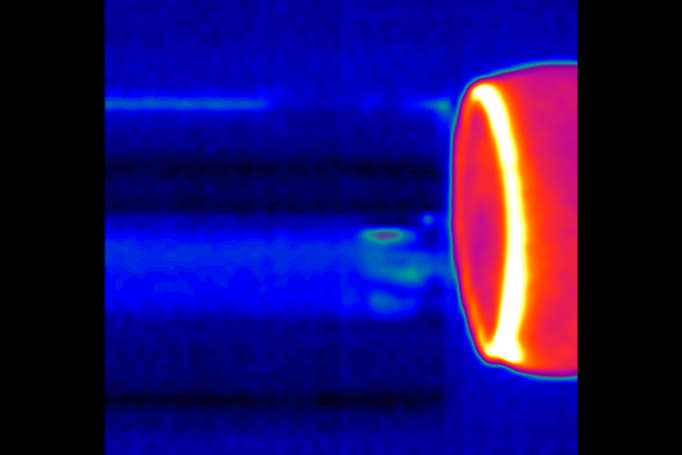

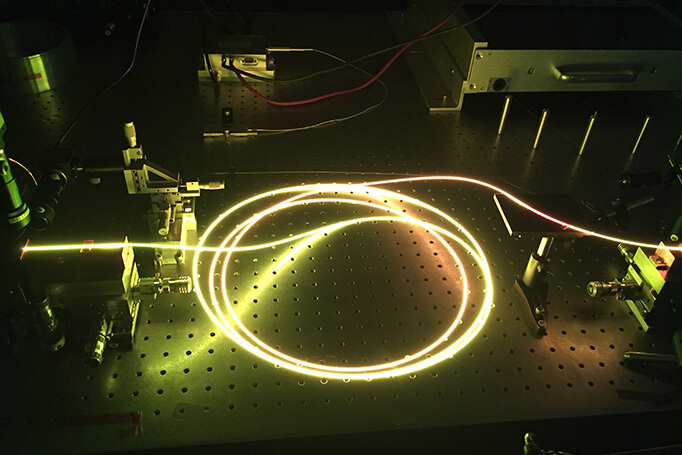

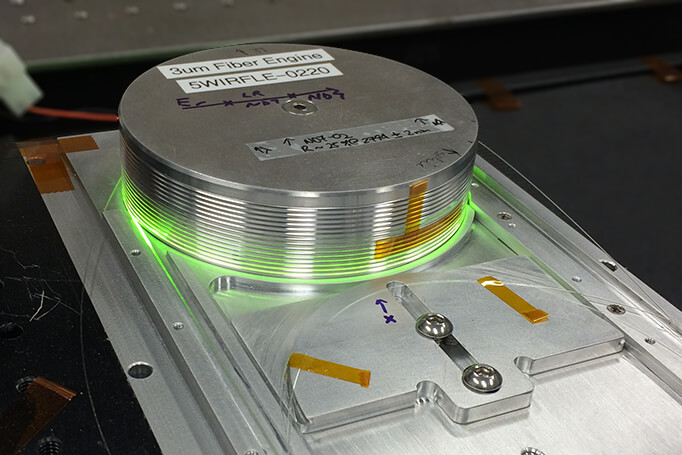

Detection of Defects in Laser Fibers

By launching a mid-infrared laser signal in a fiber core and recording its side scattering with a wide spectrum infrared camera, scientists are able to screen optical fibers for defects – an crucial step in the development of high-power infrared lasers. Images courtesy of Université Laval, Quebec, Canada.

Plasma Research

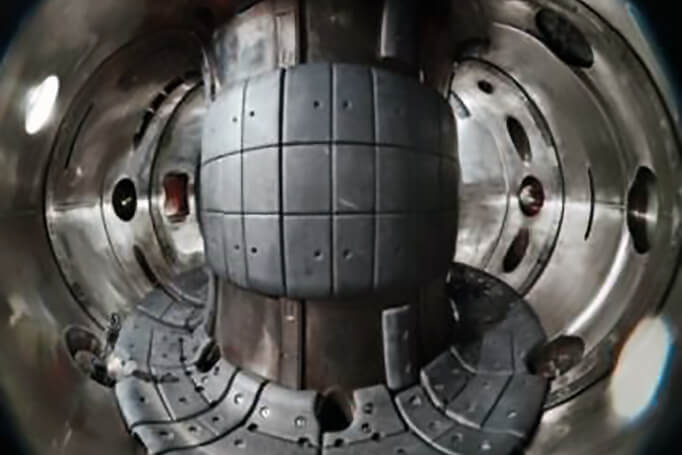

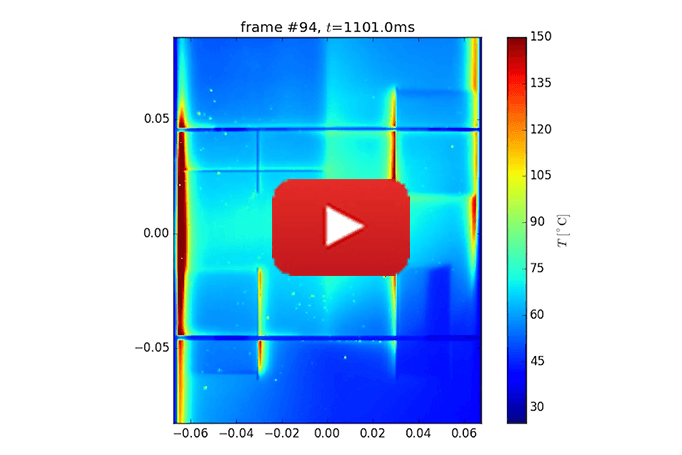

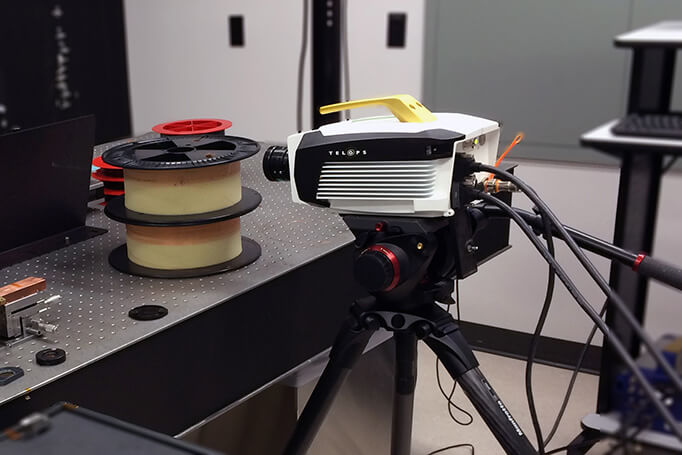

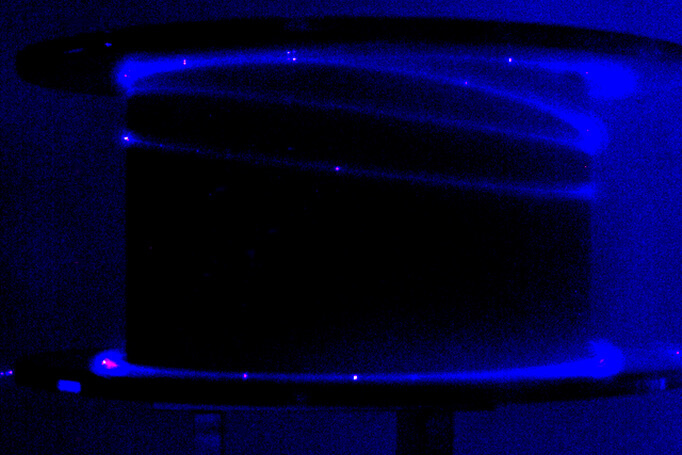

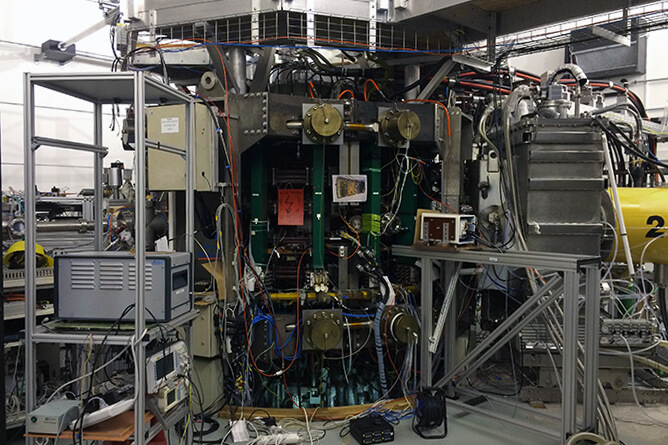

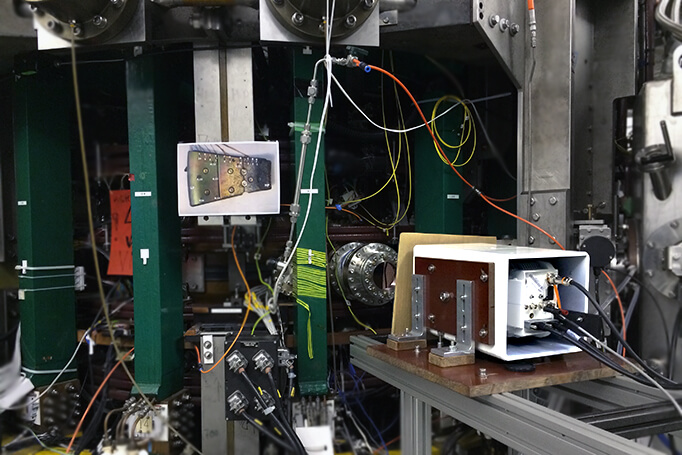

Nuclear fusion represents one of the best alternative for generating electricity in order to meet the future needs for power. Research on high-temperature and high-density plasma is carried out in tokamaks, stellarators, and helical devices. Since plasma can reach temperatures of the order of tens of thousands of degrees, it needs to be contained in a strong magnetic field. High-speed infrared imaging can help to characterize the integrity of the material forming – for example – the divertor and the armor wall during the experiments.

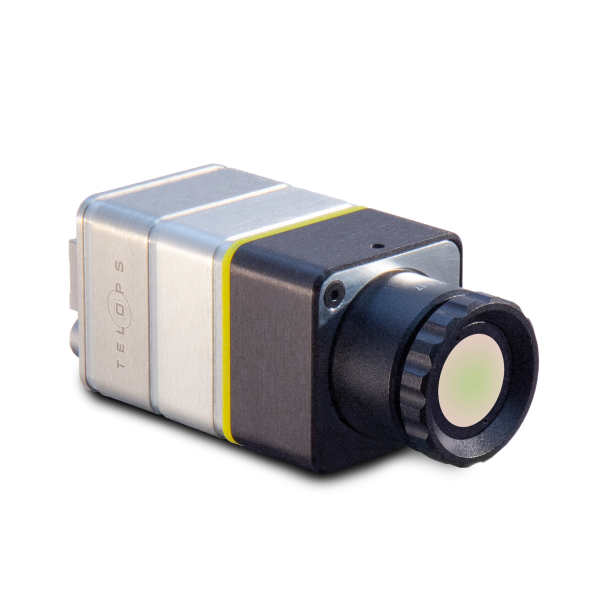

The COMPASS tokamak (bottom left) and the Telops FAST infrared camera in a Faraday cage (bottom right). Images courtesy of the Institute of Plasma Physics of the CAS (Czech Republic).

An inside view of the COMPASS vacuum vessel (left) and a video of numerical reconstruction of the plasma shape, followed by infrared footage of the graphite tiles forming the inner wall of the tokamak during plasma generation. Images and video courtesy of the Institute of Plasma Physics of the CAS (Czech Republic).

Material analysis & experimental mechanics

Precise Stress and Impact Characterization

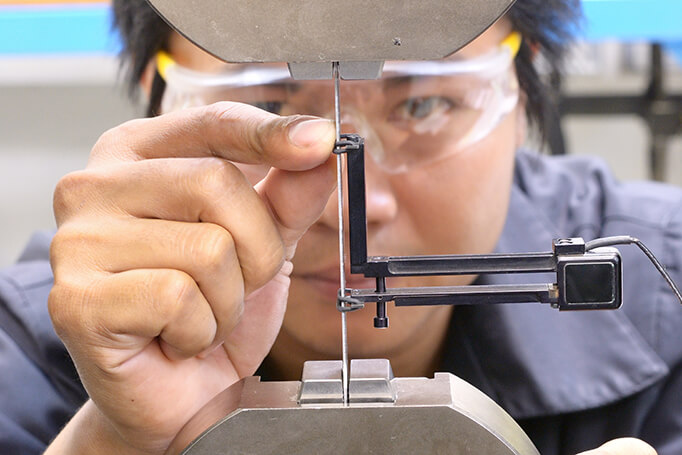

Characterization of mechanical properties such as Young’s modulus, shear strain, viscosity and fracture toughness is very important in the development process of new alloys and composite materials. Researchers typically carry out many different measurements like tensile displacement tests, compression tests and fatigue tests using extensometer and split-Hopkinson bars setups. Infrared imaging allows to characterize the energy released by the investigated material as it undergoes elastic and plastic deformation up to the fracture point.

Tensile testing of a steel rod observed in infrared using Telops’ FAST M2k. Video courtesy of University of Waterloo, Canada.

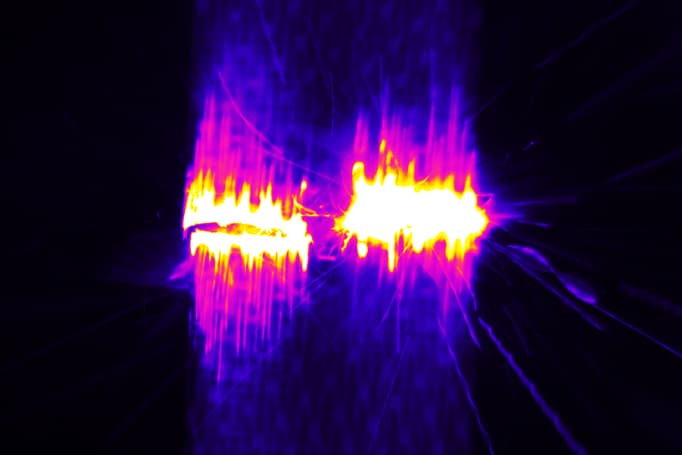

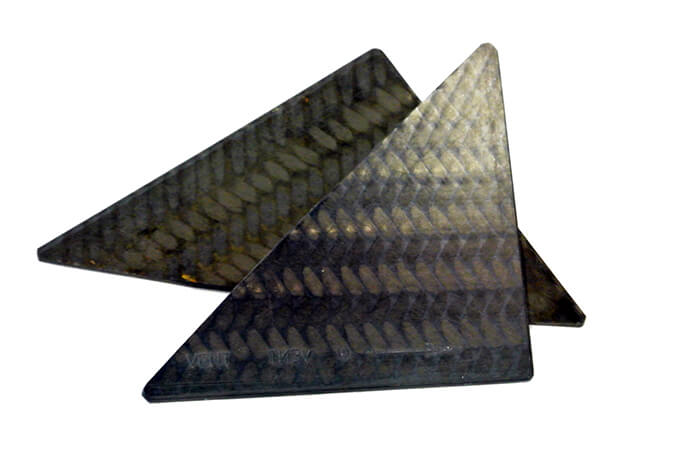

Tensile testing of a composite material observed in infrared with a Telops’ hd camera. Video courtesy of University of Waterloo, Canada.

High-Speed Infrared Imaging of a Split-Hopkinson Pressure Bar Experiment. Video courtesy of the Structural Impact Laboratory (SIMLab) of the Norwegian University of Science and Technology (NTNU).

Projectile impact observed on a composite material plate.

Products 22

See all exosens products

![Neutronic [i] Neutron Imager neutronic.](https://cdn.photonis.com/sites/default/files/styles/product/public/2022-09/neutronic.png?itok=r881fmO8)