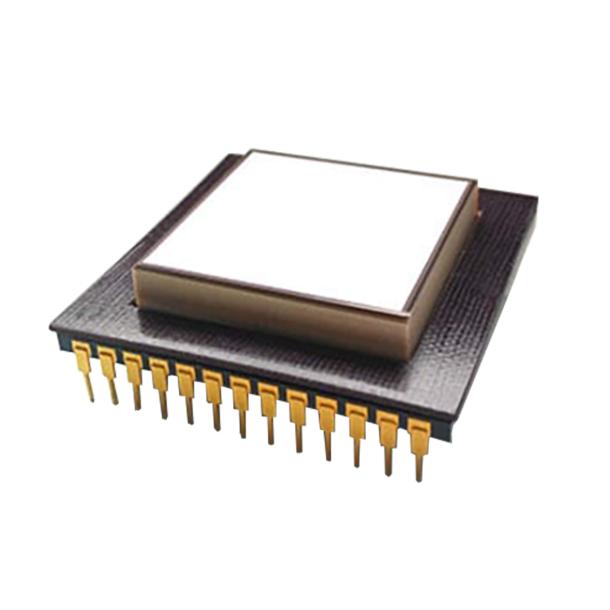

Scintillation Detectors

Generally speaking phosphor coatings are used for the visualisation of energetic photons, Soft X-ray imaging, synchrotron radiation. The phosphor coating is prepared by sedimentation of phosphor grains on a solid state sensor like CCD or CMOS Sensor. Since these sensors are usually not sensitive for a wavelength < 350nm the coating acts as a spectral converter in most cases to green light. Coated solid state sensors are a much less expensive alternative to back thinned sensors if the other advantages of these sensors are not necessary for the application.

Scintillation Detectors

Contact sales or request a quote

Contact usFeatures

Our sedimentation process leads to a very homogeneous layer structure. To guarantee a homogeneous layer structure, at least 3 to 4 layers of phosphor grains are necessary. The minimum average grain size available is 1 µm. The maximum thickness of the phosphor coating is up to ca. 25µm.

The resolution limit RL is defined as the spatial frequency resulting in a modulation transfer function MTF with a value of 3%. RL is measured in linepairs/mm (lp/mm) and can be approximated as RL = 500/D (D as the thickness of the phosphor layer in µm). Up to 80lp/mm are possible.

Scintillating Foils

The most typical application for Scintillation foils is X-ray imaging, synchrotron radiation, neutron & ion imaging. The phosphor coating is prepared by a lamination process on a substrate (plain glass, metal, or foils made of PMMA of Kapton.

Our lamination process leads to a homogeneous layer structure. To guarantee a homogeneous layer structure, at least a minimum layer thickness oh 30µ is necessary. The maximum thickness of the scintillation layer coating is up to ca. 150µm.

The screens are stable under vacuum conditions and can resist temperatures up to 400°C.

The Substrates can be provided by customer or ProxiVision can manage the procurement service of special customized substrates.